While artificial heart valves and vascular prostheses can save lives, the implants also put patients at risk, because blood clots can form on their surfaces and cause thrombosis. That’s why materials researchers in Jena are now developing thrombosis-resistant surfaces with nanostructures made from polymer crystals that can be used to control blood clotting.

By Axel Burchardt

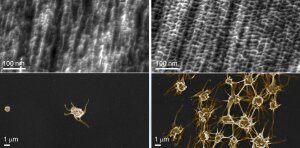

Atomic force microscopy images of nanostructured polymer surfaces (top); scanning electron microscopy images of thrombocytes on nanostructured surfaces (bottom). Different surface structures (left and right) lead to a different adhesion of platelets due to the surface-induced bioactivity of the fibrinogen.

Picture: Izabela Firkowska-Boden/Uni JenaWhen blood vessels are badly damaged or the heart valves are no longer functioning as they should, they have to be replaced. In Germany alone, around 190,000 vascular prostheses and 30,000 heart valve replacements are implanted every year. These little lifesavers are usually made of plastics, which offer many advantages but have one major disadvantage when they come into contact with blood: They can cause blood clots formation on the surface of the implants which, when detached, can lead to life-threatening complications such as thrombosis and embolisms. In order to counteract this, patients with such implants often have to take anticoagulants for a lifetime and suffer from their side effects.

Highly ordered patterns of polymer crystals

A team of researchers at the University of Jena recently developed a new approach to this issue by creating special, nanostructured polymer surfaces. Dr Izabela Firkowska-Boden, the physicist and materials scientist who led the project, explains how it was done: »When these materials are cooling down after melting, very fine and highly ordered patterns of polymer crystals can form on their surfaces under the right conditions. These crystalline structures only measure a few tens of nanometres – or a few billionths of a metre,« says Firkowska-Boden. The results of her research have been published in the American journal ›Langmuir‹.

Fibrinogen aligned along the patterns

The key to this process is the fact that the ordered patterns are about as small as fibrinogen, a protein molecule that plays an important role in blood clotting. Due to this size match and the physical forces involved in the process, the fibrinogen aligns itself along the patterns. When blood platelets (thrombocytes), which are another important factor in blood clotting, come into contact with the polymer samples treated with fibrinogen, they change. »The changes in the blood platelets depend heavily on the structure of the polymer patterns,« explains the scientist from the University of Jena. While the thrombocytes changed dramatically on one polymer pattern, thus increasing their potential for clotting, the team found that the blood platelets hardly reacted on other polymer patterns.

New design of thromboresistant surfaces of biomaterials

»From a biomedical point of view, our work shows that structuring material surfaces within the nanoscale range may allow us to fine-tune and manipulate fibrinogen bioactivity and platelet activation, which is very promising when it comes to designing new thromboresistant surfaces for biomaterials,« says Dr Firkowska-Boden. This is an important step towards making implant materials made of polymers less susceptible to blood clotting in the future.

Original-Publication:

How Nanotopography-Induced Conformational Changes of Fibrinogen Affect Platelet Adhesion and Activation, Langmuir (2020), DOI: 10.1021/acs.langmuir.0c02094External link