Unlike crystalline solids such as common metals or salts, glass does not have a regular internal structure. It is disordered, and heterogeneous on atomic scale. This poses a challenge for both glass research and industrial applications, because the internal »chaos« makes it difficult to predict and control the mechanical properties of glass. Nevertheless, scientists at the Otto Schott Institute of Materials Research are trying to find principles of order in glassy disorder – termed »correlated disorder«. Such principles can be used to improve the mechanical performance of glasses.

By Ute Schönfelder

Publilius Syrus is quoted as saying, »fortune is like glass – the brighter the glitter, the more easily broken«. And absolutely everyone is familiar with the sight of broken glass, whether it be a window that is mercilessly smashed by a football or a wine glass that breaks while washing the dishes. And yet there is also glass that can withstand tons of weight, such as the glass floors of viewing platforms or building façades. But how can the very same material be strong and fragile at the same time?

»In theory, glass is one of the strongest materials we could ever produce«, emphasizes Prof. Dr Lothar Wondraczek from the Otto Schott Institute of Materials Research. »But the actual strength is usually much lower than what we would theoretically expect«, adds the professor of glass chemistry. This prevents us from exploring its full range of possible uses and poses a long list of questions that are yet to be answered by researchers. In particular, it is difficult to predict the mechanical properties of glassy materials such as their scratch and fracture resistance. This is due to the disorder of their internal structure: predictive theory used for regular crystalline structures is not applicable for glasses.

Same composition – different properties

»Even though people have been producing glass for over 4,000 years, we’re yet to answer some of the fundamental questions about the material«, says Wondraczek. For several years now, he and his team of researchers have been focusing on the mechanical properties of glass and the development of high-strength, scratch-proof, and shatter-proof glass. »For example, we’re interested in finding out how the material’s properties can be controlled and manipulated during the production process«. In order to determine this, however, the researchers first have to understand how the molecular structure of glass (i.e., the lack of regularly arranged bonds) affects its mechanical properties.

»Even if two types of glass are exactly the same in terms of their chemical composition, they can still have completely different mechanical properties«, explains Wondraczek. After all, properties fluctuate even within the exact same object. As glass consists of »harder« and »softer« regions, it is difficult to predict the material’s macroscopic properties.

This is where Wondraczek and his colleagues come in: They are using spectroscopic methods to investigate the degree of disorder in glass and the fluctuating bond energy density within the material, in order to subsequently draw conclusions about macroscopic properties. By conducting such experiments, they can determine the distribution functions for the fluctuation of a property within a spatial ensemble. These functions can then be used to create models for predicting a material’s properties. At the same time, a very large number of artificial glasses can be created on the computer, and, with the help of machine learning, links can be identified between local disorder and the practical properties of glass.

In addition to internal disorder, surface defects (tiny flaws that are usually imperceptible to the naked eye) play a crucial role in the mechanical strength of glass. »These have a much greater influence on the properties than chemical composition«, states Wondraczek. The extent and distribution of such flaws mainly result from the production process. »We’ve shown that glass that has almost the exact same chemical composition but is produced differently reacts very differently to mechanical stress«.

Blowing hot and cold

The glass chemists now want to transfer their basic theoretical findings to practical applications and make glass surfaces more resistant to defects. In addition to glass composition and production, this can be achieved through post-processing methods. Wondraczek and his team are currently optimizing an established industrial process known as »thermal tempering«, which is used to manufacture high-strength windscreens, covers for solar panels and other glass components.

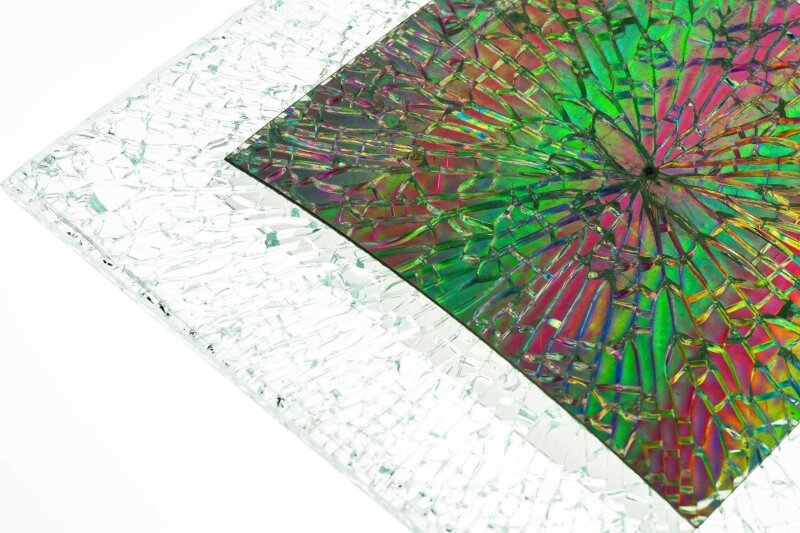

Thermal tempering causes glass to break into small crumbs in a controlled manner – instead of splintering – in the event of an accident or other damage. However, this has so far only worked for glass of a certain thickness. It must be at least two millimetres thick. For many modern glass products, however, much thinner layers play an important role today.

After obtaining a Proof of Concept grant from the European Research Council, glass chemist Wondraczek is now developing a thermal tempering process for thin-walled glass with a thickness of under one millimetre.

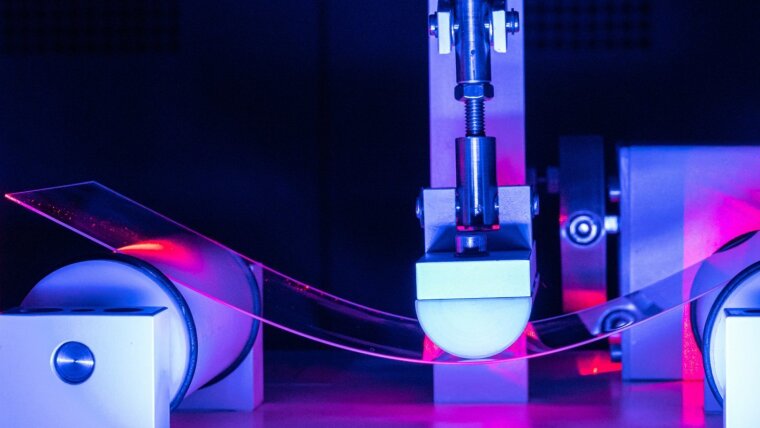

In essence, the principle is similar to conventional tempering. The glass is heated up to over 600°C and then suddenly quenched. As the surface cools down much faster than the inside of the glass, a temperature gradient is created that results in compressive surface stress that persists when the glass is completely solidified.

While thick glass is quenched simply by air, the temperature gradient created in this way is not sufficient for very thin-walled glass to generate compressive surface stress. Therefore, instead of air, the researchers are using a liquid quenching medium based on gallium alloys that melt close to room temperature, which allows them to stabilize significantly thinner glass.

Tempered glass not only has increased strength. If it does break, small, harmless crumbs are produced instead of large, sharp splinters.

Image: Jens Meyer (University of Jena)